The analysis of machine vibration is the core of Predictive Maintenance and Condition Based Monitoring Programs, a non-intrusive way of evaluating machinery health. It’s crucial that Vibration Monitoring Programs are set up properly to collect the right vibration data, in order to accurately provide Critical Asset Failure Prediction.

At Reliability Testing Services, all of our technicians are ISO–18436 certified in Vibration Analysis, cross-trained in additional technologies, with extensive field experience, ensuring that you are set up for success now and in the future.

Our goal is straight forward — Predict and Prevent Failures in Critical Assets. Managing machine issues identified through Vibration Analysis, in a planned methodology, drives a reduction in unplanned downtime, production losses and cost of operation.

Vibration Analysis can be utilized in multiple ways. We provide call out vibration services, commissioning of new installations, and routine Predictive Maintenance route-based data collection and analysis. Regardless of your needs, we will provide the right technician to do the job right. Let us know how we can assist you!

Our goal is straight forward — Predict and Prevent Failures in Critical Assets. Managing machine issues identified through Vibration Analysis, in a planned methodology, drives a reduction in unplanned downtime, production losses and cost of operation.

Vibration Analysis can be utilized in multiple ways. We provide call out vibration services, commissioning of new installations, and routine Predictive Maintenance route-based data collection and analysis. Regardless of your needs, we will provide the right technician to do the job right. Let us know how we can assist you!

Benefits from working with Reliability Testing Services include:

- Providing a safe environment for plant personnel

- Predicting and Preventing Critical Asset Failure

- Reduction of Unplanned Downtime, production losses and its associated costs

- Increased process availability leading to an increase in profitability

- Transitioning to a Planned Maintenance environment, optimizing use of Maintenance resources

- Extending the life of your Critical Assets

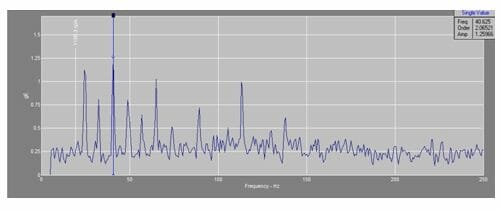

Vibration Analysis — Amplitude by Frequency

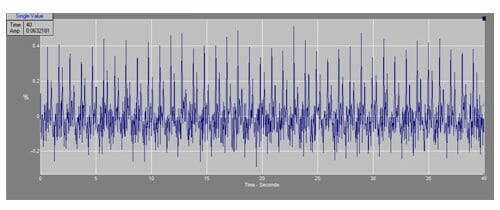

Vibration Analysis — Amplitude by Time