The most popular predictive maintenance method for a reason

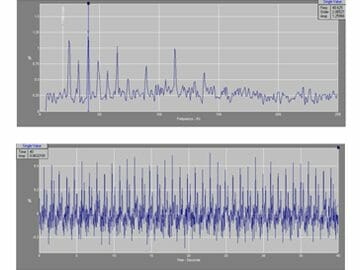

Our expertise helps clients predict machine failure before it occurs. RTS' specialists can institute a new vibration analysis regimen or support a client's existing program as relevant to their circumstances.

Achieving maximum cost savings through minimum asset downtime

Reliability of your assets is essential to remain competitive in today’s economic climate. RTS provides several Reliability Engineering services and strategies to support and improve your PdM program and equipment availability.

*Services performed by Applied Technical Services, LLC (parent company of RTSI)

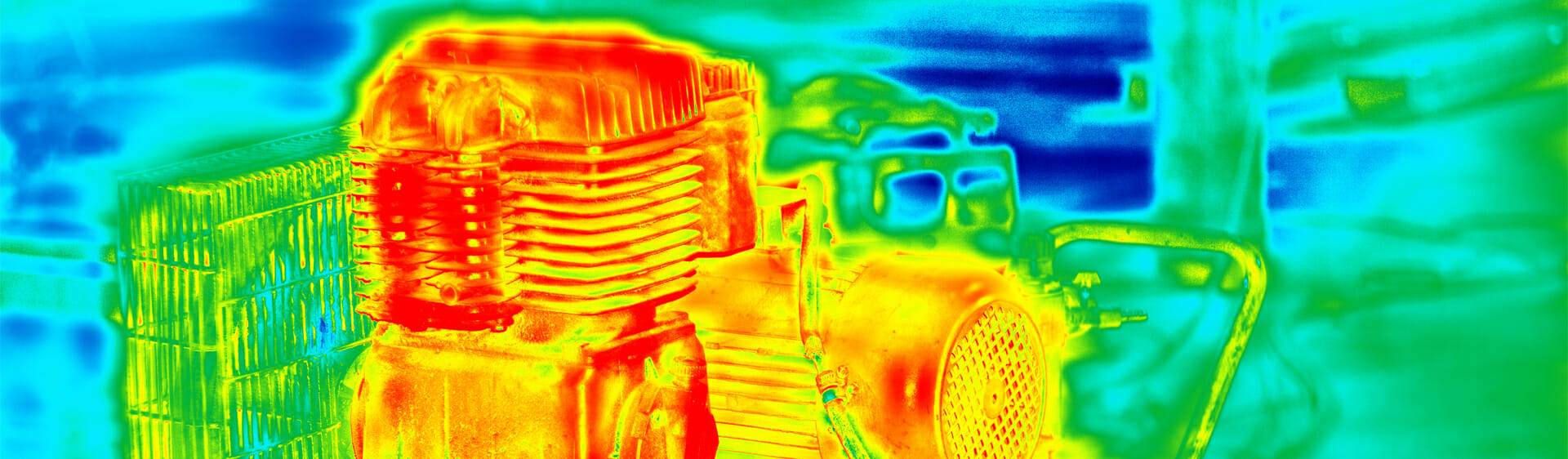

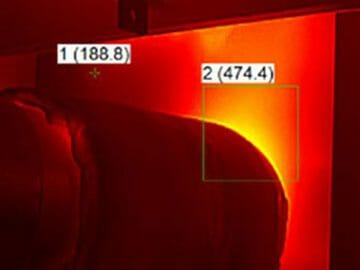

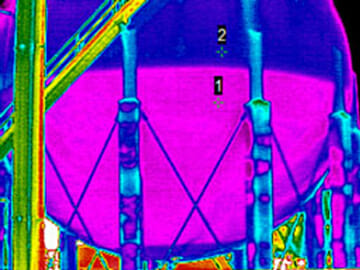

Visualize and locate deteriorating components before they fail

Infrared Thermography is an important part of any successful Predictive Maintenance Program. Documenting a critical component’s thermal condition for future comparison provides powerful insight on developing problems. Our ASNT certified technicians monitor electrical panels, switchgears, transformers, boilers, motors, furnaces, steam systems and more. Contact RTSI for a discussion about how our Infrared services can support the effectiveness of your plant’s Reliability efforts.

Reliability Testing Services, LLC

Predicting and Preventing Critical Asset Failures

Testing and Inspection

RTS’ experienced technicians specialize in locating defects and identifying underlying causes in client assets using a variety of advanced diagnostic tools and trusted testing methods.

Reliability Engineering

Reliability of your plant’s assets is essential to remain competitive in today’s economic climate. Applied Technical Services, our parent company, provides Reliability Engineering Services and Maintenance Strategies to support and improve your Predictive Maintenance Program and the reliability of your process equipment.

Predictive Maintenance

Transitioning to a Proactive strategy requires time and expertise. Our Proactive strategy approach has been proven at over 100 locations across the US, and we can do it for you too.

Personnel Training

RTS provides professional training on a wide range of predictive maintenance topics, from basics to advanced applications. Call us to discuss your needs and we’ll provide a plan that is specific to your situation.

Stop the Unplanned Downtime

Reliability Testing Services understands your goals to prevent mechanical and electrical failures, and the costs associated with unplanned downtime. Let Reliability Testing Services, LLC predict and prevent impending failures – determining which machines have problems, what those problems are and how quickly they are developing, allowing you to prioritize your Maintenance activities.

Reliability Engineering Consulting Services

What We Do?

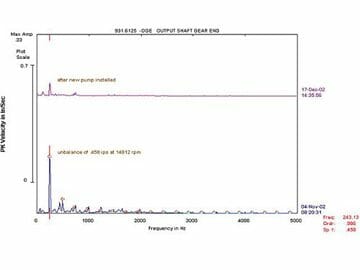

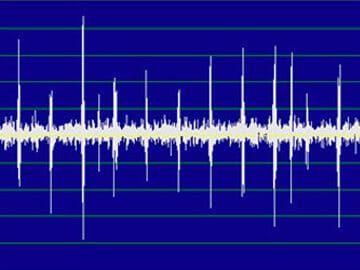

Vibration Analysis

Custom programs using predictive testing technology to establish routes, monitor frequencies and more.

Thermography

Immediate payback in the area of machine reliability, as well as real time data for most process applications.

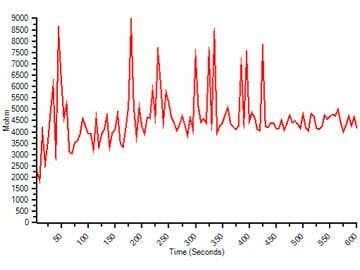

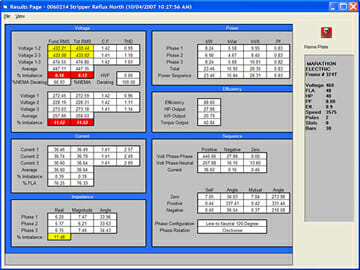

Motor Circuit Evaluation

Off-line test for motors that indicates motor stator health. Also useful in diagnosis of motor defects.

On-line Motor Testing

On-line tests for rotor condition and off-line tests for stator winding and insulation system health.

Balance / Alignment

Precision alignment to avoid catastrophic failure, expensive repairs, and, of course, costly down times.

Passive Ultrasonics

Locating and identifying the nature of many types of electrical and mechanical faults.

Reliability Testing

Integration of multiple technologies to assess machinery health and failure mode confirmation.

Training Services

Training for Level 1 & 2 thermographers and for basic AC/DC motor theory and testing technologies.

Testimonials

Our Customers

- Pulp and Paper Products

- Manufacturing

- Wood Products

- Petrochemical

- Power Generation / Transmission

- Consumer / Food Products

- Office Buildings

- Medical Facilities / Hospitals

- ....and many others!

About RTS

We have served the needs of industrial and commercial clients for over twenty years through a combination of testing and predictive maintenance services. Our company helps clients reduce downtime, increase profitability, and decrease repair costs by transitioning to a proactive maintenance culture.

Breadth of Expertise

RTS performs a wide variety of services to help clients ensure the continued efficacy of their industrial equipment. We design new predictive maintenance programs, as well as supplementing existing ones, by utilizing our testing expertise to find problems before they develop into failures.