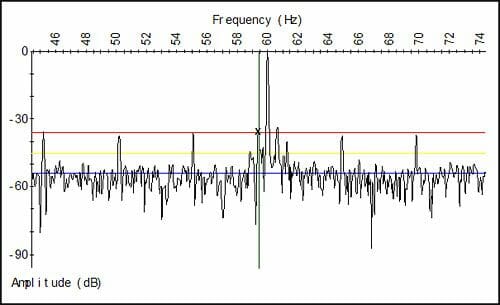

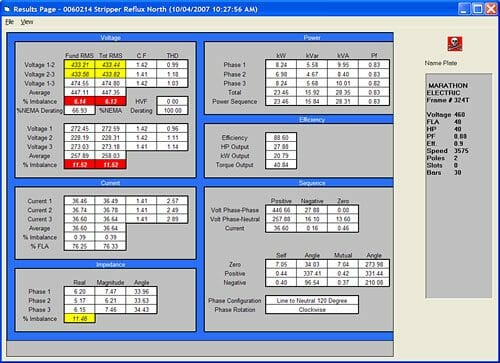

On-line motor testing is extremely useful in assessing rotor condition in induction motors as tested under normal operating conditions. This is accomplished through spectral analysis at the first and fifth harmonics of line frequency. This testing also yields current imbalance expressed as a percentage under load, and impedance imbalance as a trendable measure of stator condition.

Power quality assessment, including measures of total harmonic distortion and crest factor, is performed in those cases where voltage and current signals (PTs and CTs on any testing over 600 volts) are both available. This type of testing also offers the advantage of being non-intrusive to production operations.

Power Quality Snap-Shot

This testing provides a snap-shot of both the circuit integrity and the power quality that is servicing a motor. High resistance connections in breakers, fuses, contactors, motor lug connections, and other locations can cause voltage and current imbalances that are detrimental to motor performance, and if left uncorrected, may result in premature motor failure.

Power supply quality may also be a problem, especially in those cases where non-linear loads, variable frequency drives, excessive harmonics, or voltage imbalances exist.

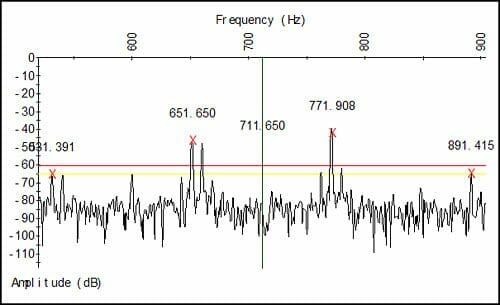

Eccentricity

This test provides a snap-shot of positional relationship between the rotor and the stator as the motor operates under load. If the rotor is not positioned with respect to the stator windings so as to provide a relatively even air gap, asymmetrical magnetic fields can be produced.

These imbalanced magnetic fields can cause undesired movement of the stator windings and electrically induced vibration resulting in pre-mature stator winding and bearing failure. Typical causes of this condition include loose or poor bearing / end bell register fits and “soft foot” mounting of the motor. This test offers excellent correlation to vibration analysis.

Rotor Testing

This test looks for anomalies in the rotor bars, rotor laminations, and the end rings of a squirrel cage induction rotor. High resistance, porosity, and breaks in rotor bars or end rings of squirrel cage induction rotors can cause excessive start-up currents and higher operating temperatures in a motor.

Over a period of time, this can result in more broken bars, and eventually lead to stator damage or failure. Analysis is performed at both the first and fifth harmonic levels.