This technology is extremely useful in locating and identifying the nature of many types of electrical and mechanical faults. Identifiable faults include bearing anomalies, steam traps, flow issues, and air / gas leaks on the mechanical side as well as arcing / tracking / corona issues on the electrical side.

The images here show a fault that was identified on a transformer high side bushing (345 kV) and the associated wave form / sound that was captured for report presentation.

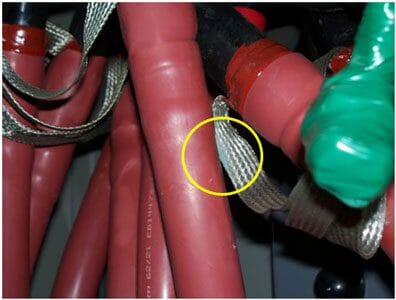

This fault was detected on a 13.8 kV stress cone. Note the blue / green “electrical fault dust” inside the yellow circle where the concentric neutral is in contact with the stress cone.

Ultrasonic Mechanical Bearing Fault

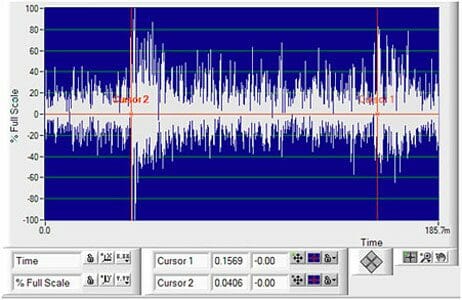

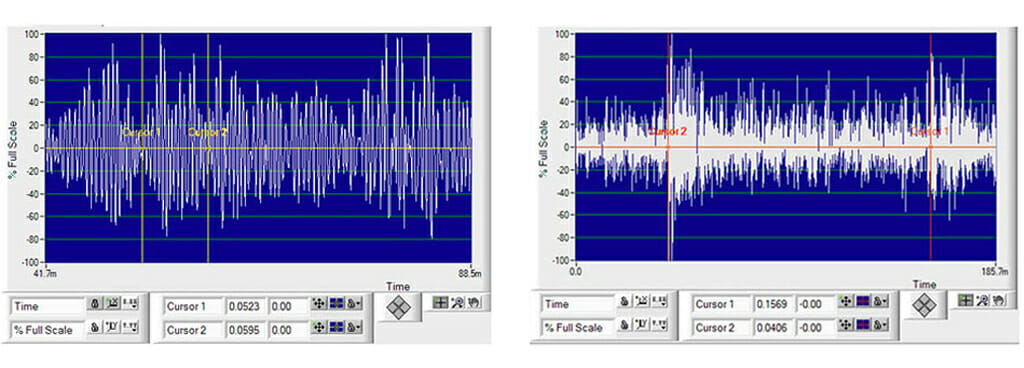

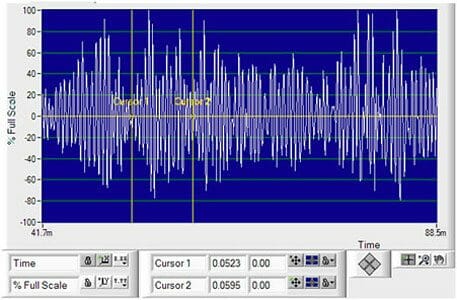

As can be seen from the acoustic time waveform, signatures that are typical of metal-to-metal impacting are occurring in this gearbox. The gearbox is the source of this noise, but the .wav is from the motor outboard bearing. The actual impacting is much more apparent here than on the gearbox since much of the surrounding “white noise” that is generated in the gearbox is not present at the motor OB bearing.

This gearbox should be inspected to determine the cause of this problem.

Sleeve Bearing

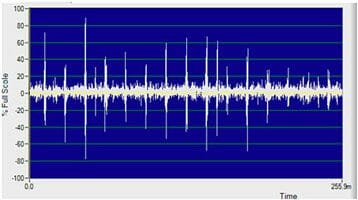

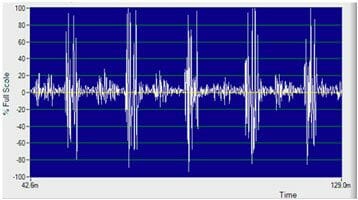

The sleeve bearing in the example here has worn to an oval shape. This resulted in a condition known as “oil whip”. The bearing has a “knock” that became very evident when recorded in the ultrasonic regions. Note the impacting that is evident in the waveform.